Science

Categories:

- Pasteurisation

- Pasteurisation Units (PUs)

- PU Control

- PU Monitoring

- PU Pick-up point

- Cold-Spot

- Accuracy

- PU Cutoffs

- Z-Values

- Thermal Degradation Units (TDUs)

- Spray Monitoring

- Pressure Monitoring

- Lethal PUs (LPUs)

- Exit Temperature

- More Information

Pasteurisation

Pasteurisation was developed and named after its inventor Louis Pasteur who in 1862 first successfully tested his method of heating wine to prevent further fermentation and spoiling. This method has been refined to extend the shelf life of wine, beer, milk and numerous other beverages and food stuffs. The pasteurisation process does not sterilise the product as the heat required for this would normally impair the flavour, however enough heat is used to allow a shelf life of up to several years.

The first pasteurisers used commercially were crude vats of water kept roughly at temperature. Bottles were loaded into baskets that were lowered into the vat for a given period of time. This labour intensive method was superseded by tunnel pasteurisation.

Tunnel Pasteurisation

In tunnel pasteurisation bottles or cans are filled and closed in the normal way,

then funnelled into the pasteuriser 'tunnel' before any labelling is added. The tunnel has a low ceiling with spray heads at regular intervals. Temperature controlled

water is sprayed down on to the packages. The bottles or cans move through the pasteuriser slowly on either a walking beam or conveyor belt.

The tunnel is divided into many temperature zones to slowly bring the product up to temperature,

keep them at a specified holding temperature and then bring them back down to room temperature.

Modern tunnel pasteurisers contain

sophisticated control systems to manage the temperatures, deal with line hold-ups and slow-downs in a way to prevent over or under pasteurisation

of the product. Water is normally recirculated to improve energy efficiency; water is preheated by spraying onto hot bottles within the cooling zones

, then the water is heated externally and sprayed onto the bottles within the pasteurising zones, before being cooled by spraying onto the cold bottles in

pre heating zones. A run through the pasteuriser takes between 20-50 minutes at temperatures from 60°C to 90°C. Due to the length of time the bottles must be

heated, tunnel pasteurisers can be extremely large. However, solutions are available with double deck designs to optimise the use of space.

-

Advantages

- Simple to install and operate

- Easy to guarantee quality

-

Disadvantages

- Take up a lot of space

- Can use a lot of energy if improperly controlled

Flash Pasteurisation

Although proposed during the 1800s, commercial flash pasteurisation only took off seriously in the 20th Century. This was when the extreme standards of hygiene required for

sterile fill technology became practical. With flash pasteurisation, product is forced through a stack of corrugated plates; the plates act as

heat exchangers to quickly bring the product up to temperature, hold it for 25-30 seconds, then cool the product back down to near ambient. The flash pasteuriser

itself is relatively compact and takes up much less room that a tunnel pasteuriser.

Flash pasteurisation must be used in conjunction with sterile fill technology and therefore has the risk of post-pasteurisation contamination

if hygiene standards are not rigorously enforced.

Flash pasteurisation is often used for the pasteurisation of bulk products such as keg beer and milk. Often when flash pasteurisation is used

for bottled or canned beer, tunnel pasteurisation is used as a secondary process for export beer in order to prolong the shelf life.

-

Advantages

- Can offer improved flavour

- Space and energy saving

-

Disadvantages

- Expensive to set up and maintain a sterile environment

- Difficult to retrofit into an existing bottling/canning line

- Risk of downstream contamination

- No possibility to independently monitor the PUs achieved

- Cannot be used for pulpy products such as Orange juice

- Cannot process more than one product without downtime

Sterile Filtration

Mentioned only for completeness this is an alternative to pasteurisation that uses advanced filters to remove sufficient microbiological contamination to

extend the shelf life of the product. This method has the advantage of having minimal impact on flavour. However, as with flash pasteurisation there is a risk

of downstream contamination.

Redpost

Redpost produces PU Monitoring equipment for tunnel pasteurisers and therefore the rest of these science pages focus exclusively on the tunnel pasteurisation of bottled and canned beverages.

Pasteurisation Units (PUs)

The Pasteurisation Unit (PU) is defined as relating to the sterilising effect observed when the product is held for one minute at a temperature termed the Base value. At this temperature therefore, 1 PU per minute is achieved.

Experiments on various mixtures of the common brewery biological contaminants showed that at temperatures over about 50°C there is an approximately ten-fold increase in sterilising effect for every 7°C increase in temperature. For example, if the time required to kill a population of micro-organisms at 60°C is found to be 5 minutes then if the temperature were to be increased to 67°C the time required would be only 0.5 minutes. The increase in temperature required to produce a ten-fold increase in kill rate is termed the Z value. The Z value in this case is therefore 7°C.

The formula for PUs is normally shown like this:

Note this assumes a Base value of 60°C and a Z value of 7°C.

The same definition is often used for soft drinks and other beverages. Where there is any possibility of spore-forming bacterial contamination being present (for example in tomato juice) very much higher temperatures are required for pasteurisation. In these situations a Base value of 80°C and a Z value of 10°C is often used.

PU Control

There are three reasons why tight control and monitoring of PU accumulation is important.

Shelf Life

First and foremost, PUs must be controlled to ensure no package on the line receives less than the minimum PU value required to reach the desired shelf life.

Failure to achieve this results in costly product wastage, repasteurisation, product recall or at worst spoiled product on supermarket shelves.

Most beer requires only around 5 PU to maintain product stability, however it is normal for brewers to aim for between 15 and 30 PU to be certain of stability.

Redpost equipment gives an instant, empirical and accurate measure of the PUs achieved, allowing longer shelf life without over-pasteurising.

Taste

The flavour of a beverage can be severely influenced by temperature, especially when the oxygen content of the beverage is high. There has been a lot of work

over many years to investigate this oxidation or staling and much improvement has been made to the filling process to reduce the dissolved oxygen content and

oxygen within the headspace.

The staling effect can be held back with the use of additives in the product, however consumer preference and in some cases national regulations can prevent

their use.

The best way to maintain flavour is to keep the number of PUs to a minimum and pasteurise at as high a temperature and for as short a time as possible. However,

this of course runs contrary to the above goal of guaranteed shelf life and can lead to problems with package vulnerability.

There has been some work to quantify the effect that pasteurisation has on flavour, Redpost equipment is able to calculate

this Thermal Degradation effect in addition to the PU result.

Energy Efficiency

With rising energy costs around the globe and consumer pressure on producers to be more eco-friendly, energy efficiency is extremely important. Until the 1950s

pasteurisation was really only based on guesswork with most beverages being extremely over-pasteurised and therefore wasting a vast amount of energy.

Since the '70s, regenerative pasteurisers have been available to improve efficiency, and better control since the '80s and '90s has improved this yet again.

Redpost monitoring equipment is able to ensure product stability without wasting energy.

PU Monitoring

Microbiological

The precursor to PU monitoring, the culturing of microorganisms from pasteurised beer, is still widely used today.

Although, whereas previously used as the sole measure of product stability, it is now used mainly as

an infrequent quality check or for research purposes. This method of monitoring was extremely slow and was often

unreliable, it was these shortcomings that led to the development of the electronic monitors available today.

Paper Chart

The first PU monitors were simple repurposed chart-based temperature loggers, travelling through the pasteuriser

in a waterproof and heat proof enclosure. They were bulky and unreliable. The logger would also not calculate PUs

directly, this had to be done by hand back in the laboratory. This was not much of an improvement on the microbiological

methods and it was this inadequacy that led Redpost to develop the first solid-state electronic PU monitor.

The modern PU Monitor

A modern PU monitor is a special purpose electronic temperature recorder, it is battery powered and housed in a rugged watertight enclosure.

The PU monitor has a means of supporting the package under test and a means of ensuring that the temperature probe stays constantly at the

PU pick-up point. The PU monitor travels through the pasteuriser tunnel with the product under test and has to operate correctly under the

high temperature, high humidity, high vibration environment inside. The enclosure must not only survive the harsh environment within the

pasteuriser but also the rough handling it may receive in the packaging hall. Above all the PU monitor should be accurate and not affect the package

under test to the extent that it becomes non-representative of the other packages on the line.

Redpost has over 30 years' experience producing dedicated PU monitors for the brewing and beverage industry.

As well as temperature and PUs, Redpost monitors are available that monitor many other variables including Spray temperature,

Pressure, Flavour Degradation and Lethal PU.

The difference a Redpost PU monitor can make can be dramatic; one new customer believed they were accumulating 20 PU, though when demonstrating

their new Redpost PU Monitor it was shown they were actually accumulating over 200PU.

Redpost equipment is regarded so highly that it is used by Pasteuriser manufacturers to calibrate the management software

when commissioning their new installations.

PU Pick-up point

This refers to the location within the package where the temperature used in calculating PUs should be measured. Redpost recommends the use of the Cold-spot as the PU pick-up point, however, some prefer to use the centre of mass of the package, or 1/3 of the way up from the bottom of the package.

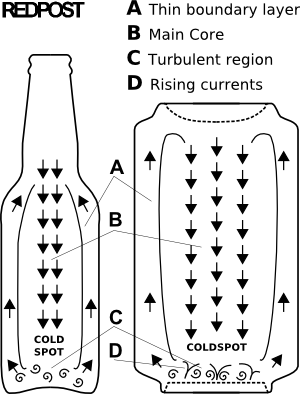

Cold-Spot

The liquid within a package cannot be considered to be a uniform mass of equal temperature. The liquid is heated by the spray water indirectly

through the walls of the package and this causes convection currents to form. Computer analysis has shown that a thin layer of heated liquid rises

quickly up the walls of the package, slowly forcing a wide column of cooler liquid down the centre of the package. At the end of the package that is in

contact with the pasteuriser bed there is a thin layer of turbulence. Above this, the wide column of falling liquid is at its coolest, this is the cold-spot.

As any microbiological component of the product is swept along with the convection currents, normal practice is to use the cold-spot as the PU pickup

point in order to get the 'worst-case' measurement for PUs. If you measure PU at the cold-spot you can be sure that all of the product has been

pasteurised to this value or higher and so can be sure you have attained your required product stability.

Accuracy

The calculation of PUs is exponential (See above). This means that small errors can affect the resultant PU values significantly. An error

of only 0.1°C in the recorded temperature can cause an error of 3.3% in the calculated PU. The accuracy should be maintained over the entire temperature

range of the pasteurising run i.e. Cutoff temperature to Maximum temperature.

It is therefore important to have a modern accurate PU monitor, all current Redpost PU Monitors offer a worst case PU accuracy of better than 8% over the

entire temperature range, incorporating all sources of error. It is common to see the errors of some

PU monitors not stated, or separated into different types and it is not made clear that these errors should be added together.

PU Cutoffs

At product temperatures below about 50°C it is doubtful that any significant sterilising effect is achieved even though from a strictly mathematical point of view the correct PU total could still be obtained, given enough time in the pasteuriser. For this reason it is desirable to set a temperature level below which no PUs are added to the total calculated by a PU monitor. This is termed the PU cutoff temperature.

Set the PU cutoff temperature at least 5°C lower than the planned product temperature in the holding zone of the pasteuriser. Higher values will give a very conservative figure for PU achieved and will reduce the repeatability of the result because the product temperature will be changing only slowly as it crosses the cutoff temperature threshold. For beer the cutoff is not normally set below 50°C.

A packaging specification will normally set the PU definition and a target PU value for each product to ensure sufficient pasteurisation. This packaging specification will have been determined by microbiological analysis.

Z-Values

The Z-Value is the parameter of the PU calculation that controls the increase in lethality with temperature. As stated above, for beer it is normally stated that for every 7°C rise there is a 10 fold increase in lethality. This means that the Z-Value is 7°C. In some fruit or vegetable juices higher temperatures are required for pasteurisation and a Z value 10°C is often used. Another alternative Z-Value for brewing is 6.94°C, this is equivalent to a value of 12.5°F and is often used in American text books.

Thermal Degradation Units (TDUs)

Sometimes called Flavour Degradation Units or FDUs.

Sometimes called Taste Degradation Units.

Thermal Degradation Units give a measure of the amount of flavour change

that has been caused by the pasteurisation process. Flavour degradation

is produced as a result of chemical reactions within the product. It is generally

accepted that chemical reactions occur twice as fast for each increase of 10°C.

From the flavour degradation

point of view it is better to achieve the PU target by using a higher temperature for a

shorter time.

The formula for TDUs is normally shown like this:

The calculated value is divided by 10 and shown as TDU/10 or dTDU. The definition therefore becomes 0.1 TDU/10 per minute at 20°C. This gives better alignment with standard PU calculation. (It gives 1.6 TDU/10 per minute at 60°C, TDU = PU at approx. 62°C). No TDUs are accumulated below 20°C. The definition does not change when working in Fahrenheit:- 0.1 TDU/10 per minute at 68°F.

A packaging specification may set a target TDU/10 value to ensure that even though pasteurising conditions may be correct the product flavour is not harmed.

TDU calculation is built into Redpost Redlink software.

Spray Monitoring

Monitoring the spray temperature is used to view the temperature of the individual temperature zones and

to identify the location of any bent or clogged spray heads. As the bed is in constant motion a sample time of at least 10 seconds is required to

determine an accurate location for a damaged head.

Delta T (ΔT) can also be measured i.e. the difference between the temperature inside the package and outside. This is

of interest when pasteurising bottles, as too great a Delta T during the heating or cooling cycles would likely lead to breakages.

The Redpost RPU-352 and RPU-353 have two temperature channels to allow measurement of product and spray temperatures.

Pressure Monitoring

During pasteurisation the pressure in the container increases. This is partly due to the rise in temperature acting on the CO2 gas already in the

headspace and partly due to the vibration, which encourages CO2 to be released from supersaturated solution in the product.

The practice of using nitrogen for purging containers and for fobbing produces a mixture of gases in the headspace that may increase the pressure rise.

Over the years there has been a trend towards ever thinner-walled can packages, as well as reduced head space volumes. Both these

factors make problems of over-pressure more significant, with peaking or breakages the result. When pasteurising cans with internal

pressure reservoirs or 'widgets' the internal pressure also needs to be monitored closely.

A PU Monitor with a pressure measurement channel can assist with this; it is attached to the bottle or can and is designed to make as little

change to the headspace of the package as possible so as not to affect the results. The graph of pressure can then be examined to

observe maximum pressure along with any obvious spikes.

The Redpost RPU-353 has a pressure measurement channel as well as two channels for product and spray temperature.

Lethal PUs (LPUs)

Lethal PUs are used by some brewers and bottlers as an extension to the PU system. Rather than having just one PU

Cutoff value, under this system there are Total-PU values and Lethal-PU values. The Total-PU cutoff would be set

at say 55°C and the Lethal-PU cutoff at 65°C the PU Monitor would then give the two PU results.

The common reason for using this methodology is as a backup to ensure that the product has completed the expected

temperature curve. With some resilient microorganisms the temperature curve is important and the product must be above

the Lethal Cutoff for a certain time to ensure stability.

Lethal PU calculation is available in Redpost Redlink software.

Exit Temperature

The temperature that the bottles or cans leave the tunnel pasteuriser can be very important. If the product leaves at too high a

temperature the flavour of the product may be affected. Because of this some package specifications state a required product exit temperature.

As the PU Monitor recording run may not be stopped immediately the product

leaves the tunnel, it may be difficult to determine the exit temperature by looking at the temperature graph alone.

To solve this problem all Redpost PU Monitors are fitted with a sensor that determines when the PU monitor leaves the pasteuriser

and the temperature of the product is recorded at this point.

More Information

There are many sources including books, journals, courses and conferences where you can find out more about the science of PU Monitoring. We would however recommend:

Excellence in packaging of beverages

Jeremy Browne and Eric Candy

Binsted Group, ISBN 095411230X.

Amazon

Binsted

Pasteurisation - a food industry practical guide

Guideline G51

Campden BRI, ISBN 978-0-905942-89-6

Campden BRI

Carbonated Soft Drinks: Formulation and Manufacture

Dr. David Steen, Philip R. Ashurst

Wiley - Blackwell, ISBN 978-1-405171-70-0

Wiley - Blackwell